Back in May, I put up a cool little tutorial on how to build a hanging desk. Basically, I attached chains to the four corners of a sturdy board and hung the board off my loft bed.

While it was a pretty simple project, the outcome was pretty cool – all the floor space that would be taken by desk legs is freed up, giving me more room to store things or to stretch out my legs.

Unfortunately, I’m back in school and the standard desk that comes with my room cannot be removed. Therefore, I had to go looking for other ways to free up floor space. Gotta make room for a couch, right?

When I moved in a few weeks ago, I walked into my new single room (yeah, RA’s get singles – be jealous) and noticed one thing – it was tiny as hell.

Seriously, it’s a 14×7 room – less than half the size of my previous room. In fact, I believe it’s one of the smallest rooms on campus.

Looking for guidance, I called the previous RA and ask him if he had any ideas on how to fit a couch in the room. He laughed and told me to get a beanbag.

Well, beanbags are pretty much unacceptable to me for the sole reason that they are not a couch. Therefore, I had to go looking to my own solution.

Here it is.

As you can see, this bed actually hangs off of a large frame rather than being supported by four legs directly below it.

Since I live in a university-owned dorm, I couldn’t screw into the walls or ceiling; everything had to be freestanding. The idea behind the bed was to create a design in which the bedposts are as close to the walls as possible. The concept is the same as that of the hanging desk – keep the floor space open.

Since the bedposts only stick out from the wall slightly, almost all of the floor became open to be molded by my inner interior designer. First step? A couch, of course!

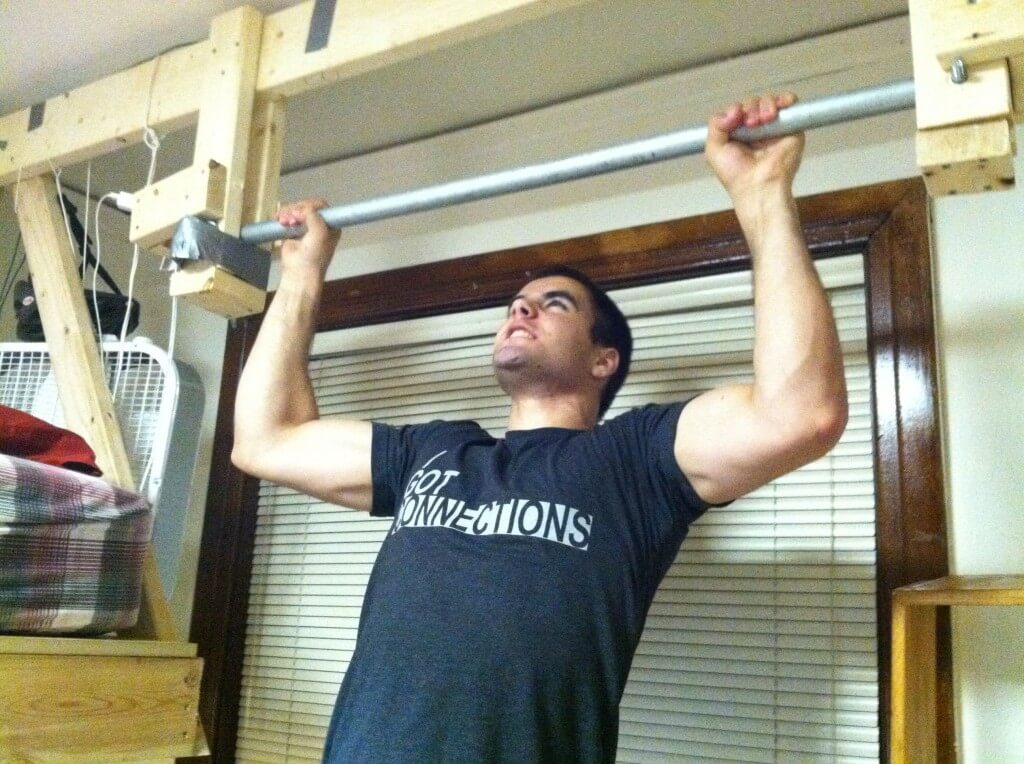

However, that’s not the only cool feature I built into this thing. When you’ve got a big frame going around your room, your creative options tend to expand; I looked at mine and decided to add… a pullup bar!

Now I can get my swole on in the comfort of my own room…

Another cool thing the frame allowed me to do was route cords and cables from one side of the room to the other easily. The pieces of tape going around the frame are securing ethernet, RCA, and other stuff.

Time to Channel Your Inner Tim Taylor.

Note: While I’d like to claim full responsibility for this bed and look like a total B O double S, I can’t take all the credit. My Grandpa Tom, the wonderful carpenter that he is, helped immensely in both the design and construction of the loft. If not for his help, the thing probably would have broke on me by now.

Alrighty then – the first thing you’re going to need to do is take very thorough measurements of your room. At a bare minimum, get these digits:

- The height of your room, floor to ceiling. You’ll want to make your posts 1-2 inches shorter than this just to make sure you’re good.

- The distance across the room. Pay attention to baseboards and ceiling trim, as well as anything on the walls that might interfere.

- The length and width of the mattress included in your room. Of course, you always have the option to make your bed bigger than the mattress, but for this tutorial’s purposes we’ll be using the exact dimensions of the bed.

You may also want to take measurements of the entire room’s length and width so you can plan the layout of the things that’ll go on the floor once the bed is off it.

Pay close attention to things in the room that may be affected by the bed. This is a frame that goes around a good portion of the room and hugs the walls, so pay attention to where it will be.

In my room, there are both a closet with a door that swings out and a bookshelf built into the wall. I had to design the bed so neither would be blocked.

The actual frame and posts aren’t the only things to consider – you’ll need diagonal “kicker” boards to provide stability on the side without the bed (if you’re building this in a single) – make sure those don’t block anything as well.

The biggest thing to remember at this point is to KNOW YOUR ROOM WELL before building this. It’s really hard to visualize your room from a casual glance, and just relying on a floor plan without seeing the room at all is just asking for trouble. You don’t want to show up to school with this thing ready to go and find out it won’t work.

Before I go on, I’d like to mention that this project is doable for two beds. In fact, I got the idea for this bed from two of my best friends who built a two-bed version for their room last year. Unfortunately, they never once took a picture of it. Still – it’s not too hard. You just build another bed on the other side of the frame.

Alright, so now that you know your room like the back of your hand and you’ve got your measurements, it’s time to nail down the design.

As I mentioned above, I recruited my grandpa and his 40+ years of carpentry/construction experience – it may be good for you to ask someone with similar experience to help if you can.

If you don’t have access to someone like that, you’ll have to use your brain as a substitute. I’m trying to provide very thorough instructions and visuals here, but projects like this rarely stick entirely to the script.

Get out a piece of paper and map out your design. Obviously, you’ll want four posts to hold the bed up, as well as four long boards to make up the frame. However, from there you can deviate and tweak the design to your liking.

For example, you can modify the actual bed portion of the design depending on what your room already comes with. In my design, I had to build an actual rectangle with a crossbeam in the middle to support the bed. This is because, in my new dorm, the bed rests on a piece of plywood that’s held up by an included loft. I had to create a design that would support this board just as well.

If your dorm comes with beds on a metal frame, you’ll have it easier than me. Since a metal frame will flex a lot less than a piece of plywood, you could just have a strong piece of wood sticking out from the front and back, and then simply lay the metal frame across since it provide all the support it needs on its own. For this tutorial’s purpose, however, we’ll assume you’ve got the plywood.

Here are some other things you can consider when designing the bed:

- How do you want to build the posts? I opted to use a 2×6 and 2×4 to build an “L” for each post. However, you could just as easily use a single 4×4 for each post and save yourself the trouble of sticking two boards together. My reasons for making the “L” shaped posts were 1) to have less wood to drill through when making holes and 2) to give each post a bit more area for a base.

- How do you want to prevent the structure from swaying on the sides not supported by walls? I used diagonal “kicker” boards that are screwed into the posts and the frame, preventing the bed from swaying. However, if you don’t have access to a table saw, it may be difficult for you to cut the 45° angles required to make these. If you have blank walls (ie. walls that don’t have closets or bookshelves in them), you could simply attach a board of equal length to that side of the frame near the bottom of the posts.

- Do you want to add any cool extras to the bed? Putting a wooden frame around the room that you own and can thus modify/screw around with opens up a lot of possibilities. Maybe you want to throw in a pullup bar like I did. Maybe you want to mount lights around the frame (please don’t create a fire hazard). Maybe you want to drill holes in the middle of the frame so you can hang a hammock. You’ve got a lot of options here – just be safe.

Got your design nailed down? Good – now it’s time to make a shopping list.

Time to Spend Like it’s Brewster’s Millions.

When I built things in the past, I did so like an artist; I just kind of built as I went along and didn’t prepare well. This practice extended to my shopping habits – I would kind of just waltz into Home Depot and buy what I thought looked good.

Things were changed for this project. Since I was going to be sleeping on this thing, I wanted to make sure everything was well thought out.

So my advice to you is to create a shopping list before you actually start buying stuff. Here’s a list of what I bought.

Keep in mind my room is little more than 8 feet across – yours may be bigger, and thus you may need to buy longer 2×6’s for the front and back of the frame.

- Six 10-foot 2×6’s (posts and long part of the frame)

- Five 8-foot 2×6’s (bed-sides of the frame and the actual bed, kickers)

- Four 10-foot 2×4’s (posts)

- Three 8-foot 2x4s’ (wood to “hang” the bed, middle brace of the bed, extra wood you might need)

- 3.5″-long carriage bolts x 30 (might be a few extra, but that’s better than having less than needed)

- Washers, lock washers, nuts (all same diameter as the bolts) – x 30 of each

- Box of 3″ long wood screws

- One tube of hot-melt adhesive and a glue gun (~$5 together)

Altogether, these materials cost me about $100. I used pine, which is cheap, so take that into consideration if you’d like to use a more expensive type of wood.

I also bought some extras, like a steel pipe for the pullup bar – but I’m not including that in the total price since it’s an optional extra.

While you’re shopping, it would be a good idea to make sure you have/have access to the following tools:

- A good power drill with plenty of juice

- Drill bits for drilling holes

- Drill bits for driving in screws (keep extras close. These tend to crap out on you the moment you need them most)

- Some sort of power saw (a circular saw works best)

- Sawhorses or something else that can raise wood off the floor for cutting/drilling/everything

- A ratchet set

- A hammer

- A tape measure (Use it. A lot.)

- A carpenter’s triangle. Really useful for drawing straight lines for cuts.

- Wood clamps. I’d suggest having at least four on hand. Seriously, these are a whole different level of helpful. Hell, you probably can’t even build this without them. I’d recommend the type of wood clamp pictured below – the quick release mechanism is really handy, and the pump-handle design is both easier and faster to use than a clamp that required turning.

Hopefully you’ve got a cool dad/grandpa/friend who has most of the stuff and who is willing to let you use it.

Now that you’ve got your list in your hand, it’s time to walk into Home Depot like a BOSS and buy your stuff. Make sure you’ve got a truck to haul it all.

Time to put the TRY in CARPENTRY.

Now that you’ve designed your bed, you have all the materials, and you’re set up in a good workspace, it’s time to step up and start building.

In my experience, it takes a good three hours to build this (with two people). After it’s built and you know it works, you’ll disassemble it and then reassemble it in your room.

Since you’ll be working for a while, why not get pumped up with my badass pump-up playlist?

Step 1: Build the posts

The first thing you’ll want to do is build the posts that will hold up this monolithic structure. This is where your 10′ 2×6’s and 2×4’s come in.

Get out your sawhorses, or whatever you’re holding up your wood with, and use your tape measure and carpenter’s triangle to mark the boards where you need to cut – this should be 1-2″ less than the height of your room. Cut four 2×6’s and four 2×4’s to that length.

Next, you’ll build the posts one at a time.

To make one, lay a 2×6 flat on the sawhorses, and then stand a 2×4 on its side on top of the 2×6. This should create an “L” shape when you look at the boards from either end.

Make sure the edges of the boards are flush, and then take your hot glue gun and lay a straight strip of glue along the length of the 2×6.

Place the 2×4 back on top of the glue strip, and clamp the two boards together with your wood clamps to allow the glue to lock in tight.

Drill in some screws along the length of the boards to make it impossible for them to separate. Once you’ve done this, you’ll end up with posts that look like this:

Step 2: Build the bed’s side of the frame

Our next step in the build process will be to join the two posts on the bed’s side of the frame. You’ll first need to cut a 2×6 to the length of the bed, and then attach each end to the top of a post. Then you’ll brace each side with kicker boards.

To start this process off, grab one of the 8-foot 2×6’s you bought. Actually – if you want to be efficient – grab four of them. You’ll need two for the frame and two for the actual bed, and since they’ll all be the same length, it makes sense to cut them all right now.

Cut each board to the length of the plywood your dorm bed rests on. Make sure it’s the same length, otherwise the plywood won’t reach one of the ends and your bed won’t be as safe.

Now that your boards are cut, set three of them aside for later. Take the one you’re using for this side of frame and get ready to attach it to the first post.

Before you begin, get out four sawhorses (or the equivalent of sawhorses) so you’ll be able to keep the whole thing off the ground and drill the holes correctly.

Once you have these set up, create a right angle with the frame board and one of the bed posts. The frame board will go on the inside of the “L” of the bed post, and it should rest on the 2×4 side of the post rather than the 2×6 side.

You don’t want it on the 2×6 side, because then the other frame board would only come into the post’s “L” about 2″. Doing it the other way will let each frame board attach to at least 3.5″ of the post, which is much more secure.

Line up the two boards and clamp them down securely with a wood clamp (it’s at this point where you’ll truly start to appreciate the wood clamps).

Now use a drill bit equal to the thickness of your bolts to drill two holes through the boards. Make sure the holes are at least a couple inches away from the vertical edge of the “L” shape, otherwise they’ll block the area that should be reserved for the other frame board.

After you’ve drilled the holes, put in the bolts.

A note about carriage bolts – you need to pound them in with a hammer to get the square bit underneath the head into the wood and lock the bolt in.

Add a flat washer and a nut and tighten it all up.

Don’t add lock washers at this stage. Lock washers put outward pressure on the nut, making it difficult to remove. This is something you want when the bed is actually being used – but it isn’t necessary during construction when you’re going to be disassembling the bed for transport once it’s complete.

Now, just repeat this process on the other side of the frame board, attaching a second post. When you’re finished, you’ll have a rectangle without the bottom side.

Now, onward to build the actual “bed”!

Step 3: Build the actual “bed”

Alright, so now it’s time to build the actual “bed” part – by this I mean we’re going to build the part that the plywood, mattress, and you (just you, riiiiiiigggghhhttttt??????) will rest on.

To start this process off, grab one of the 2×6 boards you cut earlier. This will be attached to frame part you just built in the previous step, about three feet below the other board. Attach it in the same manner – use a wood clamp the keep it where you want it, and drill holes a couple inches away from the vertical part of the “L”.

Now you’ll want to grab the last 8-foot 2×6 you bought. This will be used for the front and back pieces of the bed part, so you’ll want to cut them to be as long as the width of the plywood. Attach each one to a bed post on the vertical part of the “L”. When you’re done, you’ll have this:

Once you have this, simply complete the bed box by taking another bed-length 2×6 and screwing it into the front and back pieces. I’d use three screws for each side just to be safe.

Now, take one of your 2×4’s and cut a section to fit in the middle of the bed. Place it where you want it, and screw it in. To save on disassembling time, just screw it in on one side.

Now you’ll have something like this:

Step 4: Attach the front and back frame boards

At this point, you’ve just about got the entire bed side of the structure complete. However, you still need to add the diagonal boards that will support the weight of the actual bed, plus you. These diagonal boards attach to the front and back frame boards, so we need to add them first.

Like I said earlier, my room isn’t much wider than 8 feet, so 10-foot 2×6’s did the job for the front and back frame boards. If your room is bigger than mine – which it probably is (sigh) – then you’ll need to buy even longer 2×6 boards. This is one of the reasons why it’s really important to measure your room.

Once you’ve got the width of your room, start measuring your two 2×6’s for the cut. Don’t forget to take into account the posts.

Since these frame boards are attached on the inside of the posts, and since they’ll also be up against the sideways frame board that’s already attached, there will be three inches on each side you’ll need to take off.

Remember: Cut these boards 6 inches shorter than the width of the room.

After the boards are cut, stand them up vertically on the part of the post they’ll be attached to, clamp them up, drill your holes, and get those bolts in.

Now you need to attach the diagonal boards that will support the weight of the bed and you. Take a 2×4 and hold it up to the bed, placing one end at next to the top of the bed post and the other at the edge of the bed itself. Clamp it down, and draw cutting lines on the boards so you can cut them at the right angle to be flush with everything. Unclamp the board and cut the angles with a table saw if you’ve got it.

Another option: It may actually be easier just to make the board go straight from the edge of the bed up to the same point on the frame, instead of making it diagonal. There’s no downside to this – me making the boards diagonal was purely an aesthetic choice. In fact, if it’s difficult for you to cut the boards at the correct angles to do the diagonal boards, I’d encourage you to do vertical supports rather than have edges sticking out all over the place.

Anyway, I’d recommend drilling holes for bolts at both ends of each board, and I’d also screw these in when it’s all said and done. These two boards will be supporting almost all of the weight, and call me a paranoid psycho freak, but overkill just seems better than dying to me.

Once you’ve got support boards in place, flip the entire structure upside down so it’s in place when you’re ready to attach the other side of the frame.

Step 5: Build and attach the other side of the frame

The end is in sight now. All you’ve got to do to finish construction is build the other side of the frame, and then slap that baby onto what you’ve already got.

Start out by taking your last bed-length 2×6 and attaching it to the final two bed posts, just like you did with the other side. The only different here is that, once you’re done, you need to add kicker boards for support.

Since this side of the bed doesn’t have, well, a “bed” attached to the middle, it doesn’t have much keeping it from swaying. Kicker boards solve this problem.

Grab a couple of scrap 2×6 boards left over from other cuts to make the kickers. If you have a table saw, this should be really easy: just set the saw to cut a 45° angle, and run each side of the board through.

If you don’t have a table saw, you can do this with a jig saw or a circular saw – it’s just harder. Don’t cut off any fingers.

Once your kickers are cut, just screw them into both the posts and the frame board. You should have something like this:

Now, just flip the whole piece upside down and attach it. Congrats, you now have a fully-built (upside-down) hanging loft!

Don’t reach for that grape soda just yet though, broseph – you still need to get this thing into your room. That’s going to require you to…

Step 6: Disassemble, Transport, and Reassemble!

Now I know what you’re thinking…

“Disassembling should be easy! All I’ve got to do is pull out all the bolts and I’m set!”

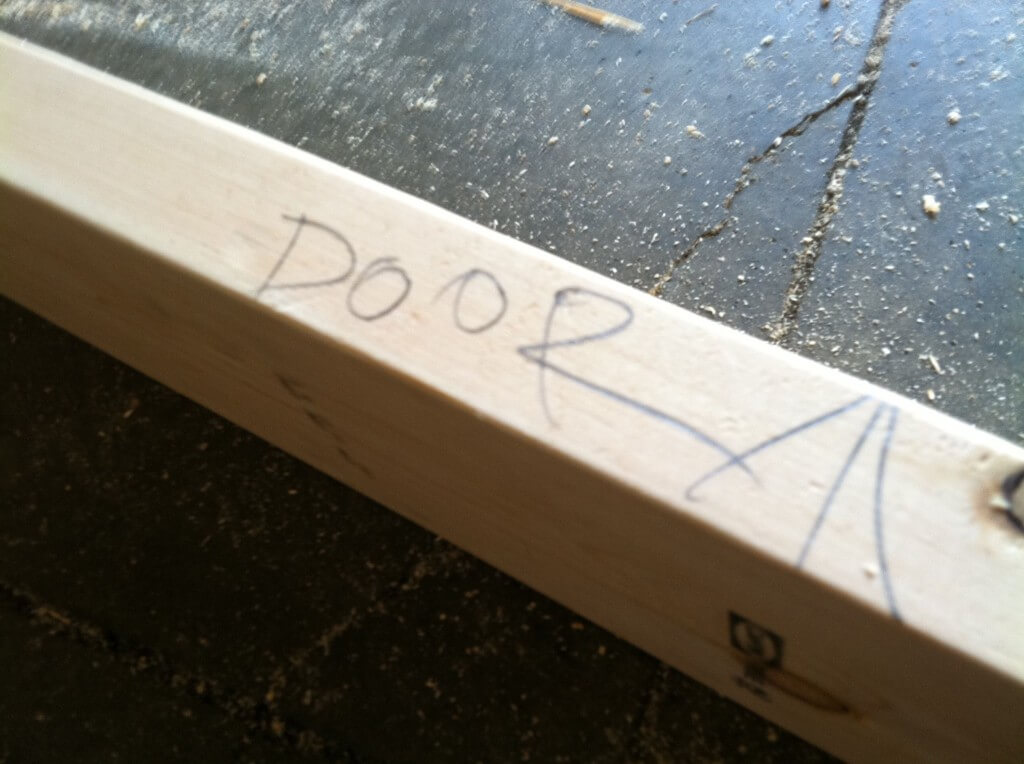

Slow down there, Quick Draw McGraw… you’re forgetting one critical thing. You need to label the poop out of this bed.

No matter how precise you were with your drilling and other such building activities, it’s inevitable that not everything is uniform on the bed. Holes will have slightly different positions on each of the four corners, the wood might be warped in certain spots, etc.

My point is, if you mix up your pieces during reassembly, you may not get this bed back together when it really counts. So grab a pencil and mark the bed up until you’re certain you can get it back together exactly like it is now.

Once everything is labeled, then you can take it all apart, load it up in the pickup, and drive merrily off to college.

Reassembling the bed in your room is a fairly straightforward process. However, things can still creep up and bite you in the butt if you’re not prepared. With that in mind, here are a few reassembly tips from my own experience:

- Bring more tools than you think you need. You won’t need everything you used to build the bed, but you should still be prepared. Bring a handsaw in case you need to make small cuts, a hammer for pounding in/removing stubborn bolts, and duct tape for… anything really.

- Of course, you’ll need a power drill for driving in screws and a ratchet for tightening down the bolts.

- Bring a few extra screwdriver bits for the drill.

- Bring an extra battery for the drill.

- Don’t forget important things like your nuts and bolts at home.

- Bring some bros to help assemble the loft.

- Bring a stepping stool if all your dorm furniture is on wheels like mine is. Standing on a wheely desk while trying to build a loft is not safe or fun.

- Remember to put the lock washers on this time around. They go on after the flat washer but before the nut.

- Thank whoever helped you build this loft. Make them cookies or something.

Step 7: ????

Step 8: Profit!

You should now have a fully assembled hanging loft bed of epic proportions.

Now it’s time to customize: tack on a pullup bar, lighting (maybe Christmas lights?), or whatever. One thing I’d suggest adding is some sort of obstruction that will prevent you from rolling out of said epic bed. It’s up to you though.

So here’s my finished bed! The question now is…. can you make something even cooler?